- This topic is empty.

-

AuthorPosts

-

2025-07-28 at 11:53 am #4246

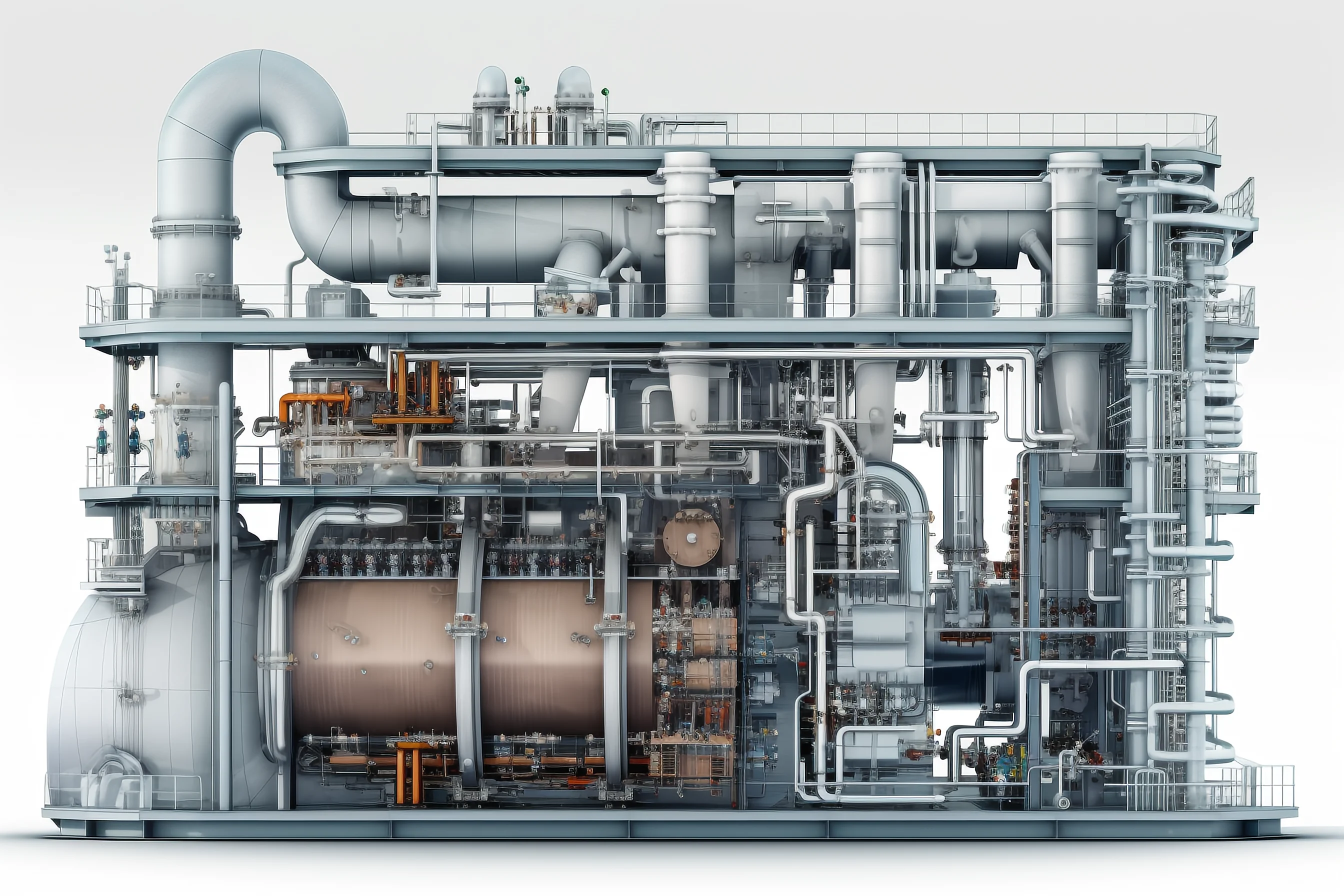

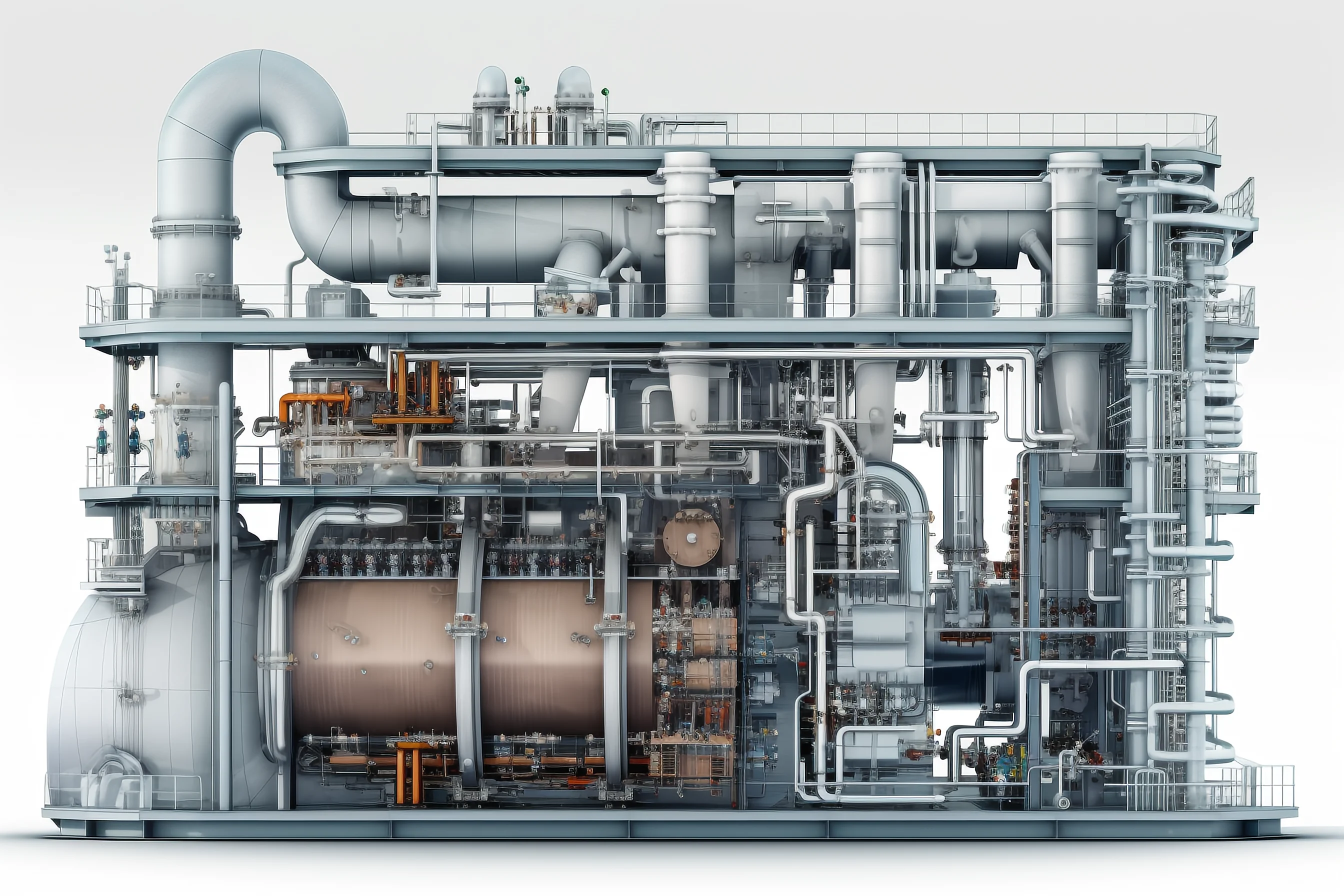

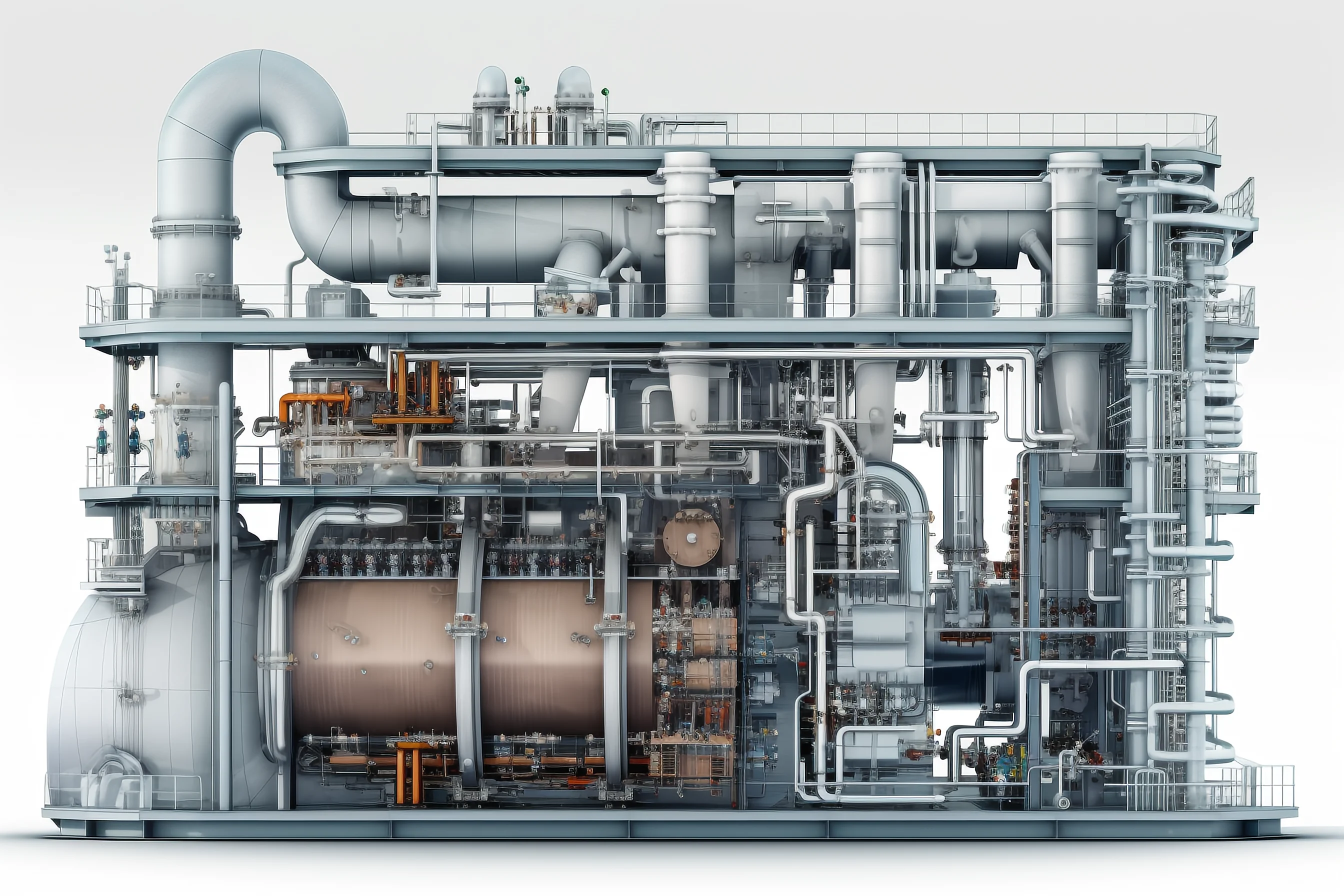

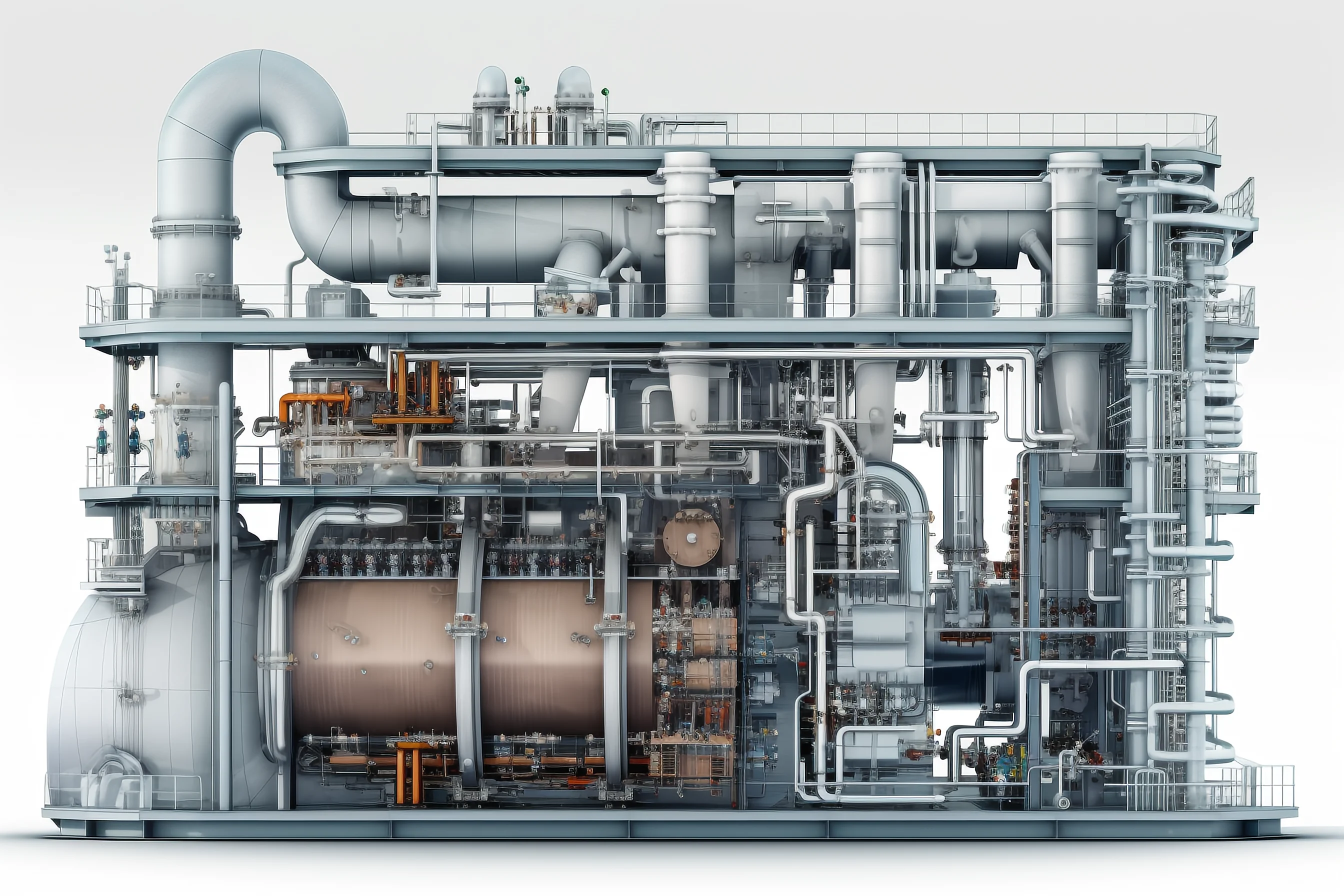

In the evolving world of chemical process engineering, flexibility, safety, and scalability are vital. One technology that has gained rapid popularity for its versatility and practicality is the skid-mounted stirring kettle unit. Compact, modular, and ready-to-deploy, these systems are transforming how chemical reactions and material mixing are carried out in laboratories, pilot plants, and production environments.

As a leader in this field, Chem-Unit offers industry-grade, customizable skid-mounted systems that are purpose-built for research institutions, chemical manufacturers, and new materials developers. Let’s explore the top six applications where these systems deliver significant value in chemical processing.

1. Chemical Reaction and Synthesis

Skid-mounted stirring kettle units are essential in reaction engineering, enabling precise control over temperature, mixing speed, and pressure conditions. Whether it's for exothermic or endothermic reactions, these systems allow chemists and engineers to conduct batch and semi-continuous synthesis with accuracy and safety.

Why It Matters:

Sealed environments for reactive substances

Integrated heating/cooling jackets for temperature control

Scalable from lab testing to pilot production

Chem-Unit Advantage: Offers vessels built with corrosion-resistant materials (e.g., Hastelloy, SS316L) and explosion-proof instrumentation for demanding synthesis processes.

2. Emulsification and Dispersion

In industries like cosmetics, coatings, and specialty chemicals, stable emulsions and dispersions are key. Skid-mounted stirring kettles provide consistent shear and mixing performance needed to blend immiscible liquids or disperse solids uniformly in liquids.

Why It Matters:

Homogeneous mixing through variable-speed agitators

Optional inline homogenizers or high-shear mixers

Temperature-sensitive formulations supported

Chem-Unit Advantage: Custom agitator configurations (anchor, turbine, propeller) matched to your formulation’s rheology.

3. Pilot-Scale Process Development

Pilot-scale testing is the bridge between laboratory research and full-scale production. Skid-mounted systems make it easy to replicate, refine, and scale chemical processes under near-production conditions.

Why It Matters:

Flexible setups for multiple process variables

Cost-effective and quicker than building fixed installations

Real-time data collection and process monitoring

Chem-Unit Advantage: Expert design of pilot systems that simulate commercial conditions, with automation interfaces for SCADA or PLC systems.

4. Crystallization and Precipitation Processes

In pharmaceuticals and fine chemicals, controlled crystallization is crucial for purity and particle size distribution. Skid-mounted units allow close control of nucleation and growth phases during batch crystallization.

Why It Matters:

Temperature and agitation control for consistent crystal formation

Jacketed designs for rapid cooling or heating

Ease of cleaning to avoid cross-contamination

Chem-Unit Advantage: Supports multi-step crystallization setups with auxiliary filtration or centrifugation modules.

5. Heat Transfer and Thermal Conditioning

Skid-mounted kettles often serve as heat exchangers or thermal conditioning units, especially when preheating or cooling reactants before a primary process step. Integrated temperature controls help maintain consistency.

Why It Matters:

Reduces energy waste by optimizing thermal balance

Enables step-wise processing

Helps maintain ideal reaction conditions

Chem-Unit Advantage: Offers precise temperature control systems with safety interlocks and automatic adjustments.

6. Material Testing and Formulation Trials

For new material development, such as advanced polymers, battery slurry formulations, or nanomaterials, skid-mounted stirring kettles provide a controlled environment for iterative experimentation.

Why It Matters:

Enables safe and repeatable testing of novel compounds

Easy to reconfigure for different test parameters

Can simulate production conditions for feasibility studies

Chem-Unit Advantage: Integration with experimental robotics and digital control platforms for unmanned trials and AI-supported research.

Why Choose Chem-Unit for Skid-Mounted Kettle Solutions?

Chem-Unit is a recognized innovator in the field of modular process equipment, offering:

Customized design and fabrication

Rapid deployment with plug-and-play functionality

Support for process automation and remote diagnostics

Full lifecycle technical support—from R&D to production scale-up

Their products are widely trusted in research institutes, chemical labs, and emerging tech companies that need agile, high-performance solutions.

Conclusion

From process development to material synthesis, skid-mounted stirring kettle units are revolutionizing chemical engineering operations. Their portability, configurability, and process control capabilities make them ideal for a wide range of industrial and research applications.

Backed by Chem-Unit’s technical expertise and manufacturing excellence, these systems are not just tools—but strategic assets for driving innovation in the chemical process industry.

Looking to boost your chemical processing capabilities? Chem-Unit offers the complete solution.

How Skid-Mounted Stirring Kettle Units Improve Mixing Efficiency and Portability

en.chem-unit.com

Shanghai Chem-Unit Technologies Co. Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.