- This topic is empty.

-

AuthorPosts

-

2025-07-09 at 5:57 pm #3983

In the dynamic world of polyurethane (PU) manufacturing, precision and consistency are essential for delivering high-quality products. One of the most critical components in the polyurethane processing chain is the mix-head. Specifically, low pressure mix-heads have carved out a vital niche in applications that require flexibility, reliability, and cost-efficiency. This article explores the pivotal role that low pressure mix-heads play in polyurethane processing and highlights how global leaders like Haifeng are revolutionizing the industry with advanced equipment and system innovations.

Understanding Polyurethane Processing

Polyurethane is a versatile polymer used in various industries, from automotive and furniture to construction and footwear. The production process involves mixing two main components—polyol and isocyanate—along with catalysts, blowing agents, and other additives. Achieving the correct chemical reaction requires precise metering and homogeneous mixing, which is where the mix-head becomes indispensable.

What Are Low Pressure Mix-Heads?

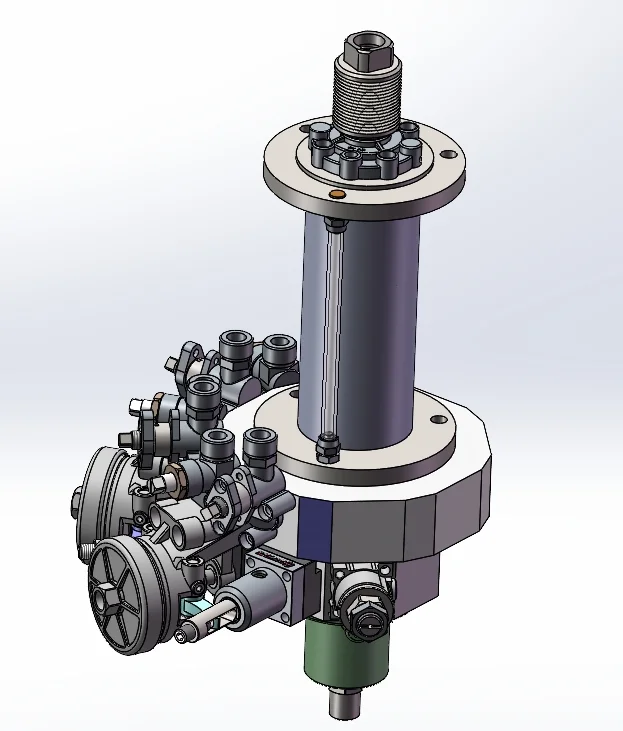

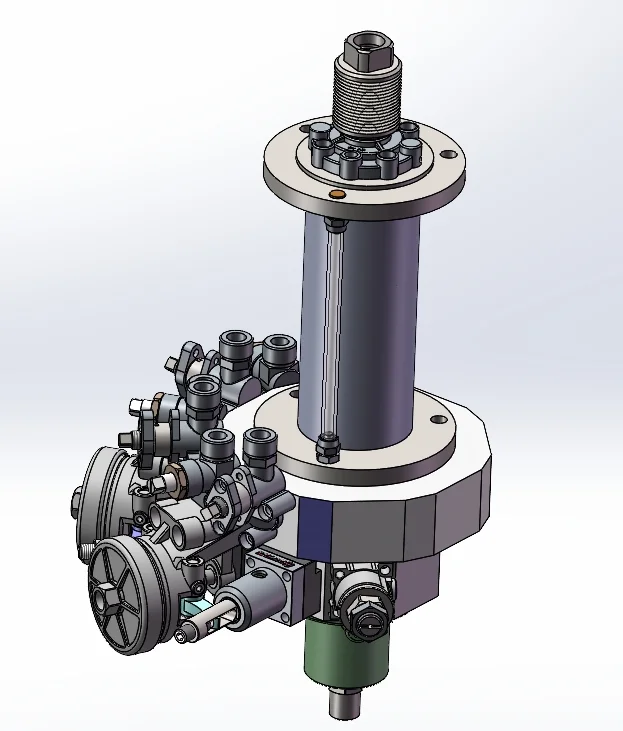

Low pressure mix-heads are specialized devices used in PU systems where the raw materials are metered and mixed at relatively low pressures (typically below 200 bar). Unlike high-pressure systems that rely on impingement mixing, low pressure mix-heads use mechanical mixing methods, such as rotating blades or stirrers, to blend the components within a chamber.

These mix-heads are ideal for:

Flexible foam production

Casting applications

Elastomers and adhesives

Small- to medium-scale manufacturing

Key Benefits of Low Pressure Mix-Heads

1. Cost-Effective Operation

Low pressure systems generally require less energy and are less expensive to maintain. They also tend to have longer equipment lifespans due to lower mechanical stress on the components.

2. User-Friendly Maintenance

Cleaning and maintenance are simpler compared to high-pressure systems. Many low pressure mix-heads are equipped with self-cleaning or solvent-rinsing functions, which reduce downtime and ensure consistent product quality.

3. Process Versatility

Low pressure mix-heads are highly adaptable, making them ideal for custom formulations and small production runs. They allow for a greater range of additives and pigment incorporation, giving manufacturers more control over product characteristics.

4. Safety and Environmental Considerations

Operating at lower pressures inherently reduces the risk of accidents. Moreover, advancements in design—such as closed-loop flushing systems—minimize environmental impact.

Haifeng: Innovating for the Future

As one of the world’s leading manufacturers of polyurethane production and processing equipment, Haifeng has consistently pushed the boundaries of technology to meet evolving industry demands. Haifeng’s low pressure mix-heads are engineered with cutting-edge features such as:

High-precision dosing systems

Modular design for easy customization

Advanced automation interfaces for Industry 4.0 integration

With a global footprint and decades of experience, Haifeng serves a wide range of sectors, providing not only equipment but complete system solutions that enhance production efficiency, reduce waste, and ensure product excellence.

Applications in Real-World Industries

Haifeng’s low pressure mix-head technology is used worldwide in:

Automotive seating and insulation panels

Flexible and rigid foam furniture

Footwear midsoles and outsoles

Construction panels and thermal insulation systems

Each application benefits from the precise control and reliability offered by Haifeng’s mix-head systems, helping manufacturers achieve superior performance and durability in their PU products.

Conclusion

Low pressure mix-heads continue to be a cornerstone of polyurethane processing, offering unmatched flexibility, ease of use, and cost advantages. As industries push for more sustainable and efficient production methods, these systems will only grow in importance. With companies like Haifeng leading the charge in innovation and global deployment, the future of polyurethane manufacturing looks not only efficient but also exceptionally bright.

Whether you are launching a new polyurethane product line or enhancing your current production setup, choosing a high-quality low-pressure mixhead can significantly improve your production efficiency and product quality.

Applications of Low Pressure Mix-Heads in Molded Foam Manufacturing

http://www.haifeng-automation.cn

Haifeng -

AuthorPosts

- You must be logged in to reply to this topic.