- This topic is empty.

-

AuthorPosts

-

2025-06-06 at 2:52 pm #3689

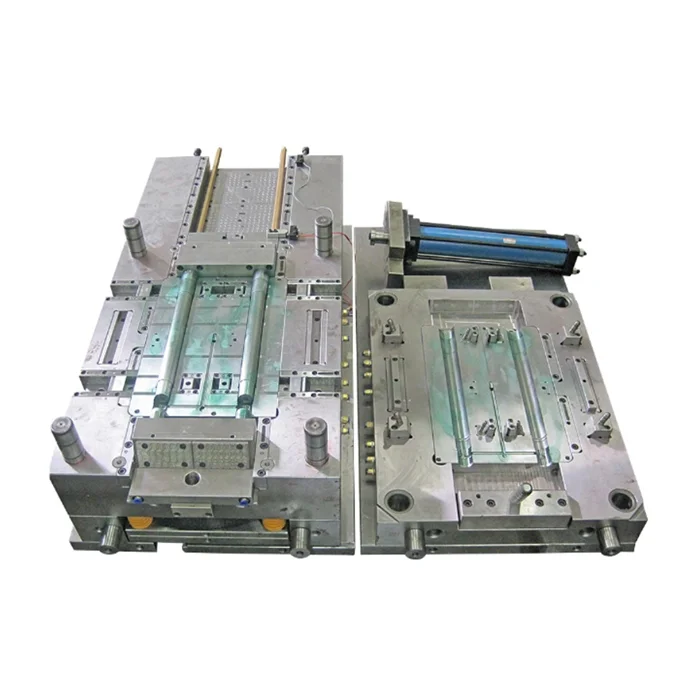

Injection molds used in the manufacturing of vacuum cleaner components play a pivotal role in ensuring part quality, production efficiency, and product durability. Among these, *custom precision molds* for vacuum cleaner housings, filters, and accessories are especially critical due to the high dimensional accuracy and surface finish requirements. These molds are typically complex, incorporating intricate geometries, moving components, and fine tolerances. In this blog post, Xuzhong, as a high performance injection mold products manufacturer, will share the maintenance of custom precision vacuum cleaner injection mold for sale.

1. Importance of Mold Maintenance in Precision Vacuum Cleaner Manufacturing

Precision molds for vacuum cleaner components – such as motor housings, nozzle heads, dust container lids, and filter frames – must produce parts that are dimensionally consistent, visually defect-free, and functionally robust. The quality of the mold directly translates to the quality of the product. Without regular and structured maintenance, even the most finely crafted mold can deteriorate quickly, leading to flashing, parting line mismatches, sink marks, or misalignment of inserts.

Moreover, vacuum cleaner parts often involve multi-material or overmolding processes (e.g., soft-touch grips or transparent dust bins), which impose additional thermal and mechanical stress on the mold. This makes preventive maintenance and component-specific care even more vital.

2. Types of Maintenance: Preventive vs. Corrective

There are generally two types of mold maintenance strategies employed in injection molding facilities:

* Disassemble major moving components if applicable.

* Use lint-free wipes and mold-safe solvents to remove grease, residues, or plastic debris.

* Apply compressed air (dried and filtered) to clear dust or particulate matter.

* Conduct a pH-neutral detergent wash for parts exposed to corrosive or hygroscopic resins.

* Finish with a corrosion-inhibiting mold protector if the mold will be stored for a prolonged period.

Avoid using aggressive abrasives or unregulated ultrasonic cleaning for fine-tolerance molds, as these can alter surface textures or critical dimensions.

3. Lubrication Guidelines

Correct lubrication is vital to reduce wear and ensure smooth movement of components. For vacuum cleaner molds, which may run at high cavitation or under fast cycle times, select lubricants that are:

* High-temperature resistant

* Non-carbonizing

* Resin-compatible (e.g., non-reactive with polycarbonate or ABS)

* Food-grade (if required by environmental standards)

Apply lubricants sparingly but thoroughly, particularly on:

* Ejector pin bushings

* Cam sliders and lifters

* Guide pins and bushings

Over-lubrication can attract contaminants and cause buildup, leading to premature wear or functional issues.

4. Inspection and Documentation

Every maintenance event – whether preventive or corrective – should be logged with detail. A robust mold maintenance record includes:

* Date and time of inspection

* Mold ID and cavity/core number

* Observations (e.g., wear marks, corrosion, part defect correlation)

* Actions taken (cleaning, part replacements, polishing, etc.)

* Next scheduled maintenance

Advanced facilities integrate *digital mold monitoring systems* that track temperature cycles, injection pressures, and component wear predictions using IoT sensors. These systems can alert maintenance personnel to potential issues before they result in product defects or mold damage.

5. Common Maintenance Issues and Troubleshooting

Issue

Possible Cause

Suggested Action

Flashing at parting line

Worn shut-offs or improper clamping force

Re-machine or shim shut-offs, verify press tonnage

Burn marks

Blocked vents or trapped air

Clean and re-machine venting grooves

Short shots

Clogged gates, cooling imbalance

Check runner system, inspect heating/cooling channels

Part sticking

Worn ejector pins or misalignment

Polish ejector surfaces, check for wear or bending

Surface blemishes

Mold deposits or corrosion

Clean mold cavities thoroughly, apply rust inhibitor

6. Storage and Long-Term Preservation

When molds are taken out of rotation for weeks or months, appropriate storage is crucial:

* Apply rust inhibitors to all exposed steel surfaces.

* Plug all water lines to prevent internal condensation.

* Store in a humidity-controlled environment.

* Use protective covers to prevent dust accumulation.

For molds used in transparent or optical-grade vacuum cleaner parts (e.g., clear dust bins), special anti-fog or anti-static coatings may be applied before storage to preserve surface fidelity.

Conclusion

The maintenance of custom precision vacuum cleaner injection molds is a highly technical discipline that combines mechanical insight, materials science, and meticulous procedural adherence. With rising quality standards and shrinking margins in the home appliance sector, mold longevity and part quality can no longer be treated as reactive concerns – they must be proactively engineered through a disciplined maintenance regime.

http://www.xuzhongmold.com

Xuzhong -

AuthorPosts

- You must be logged in to reply to this topic.