- This topic is empty.

-

AuthorPosts

-

2025-11-17 at 3:27 pm #5378

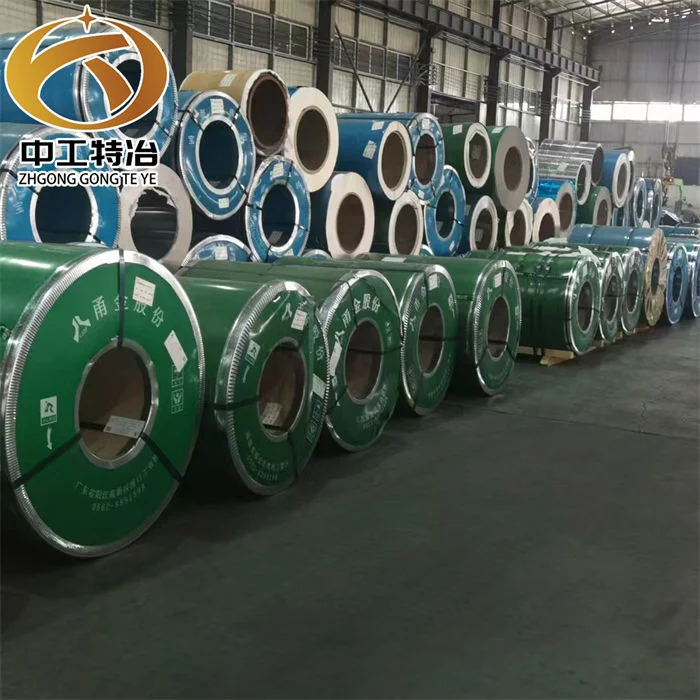

In the world of modern manufacturing and construction, stainless steel has secured its reputation as one of the most reliable and versatile materials. Among the many forms of stainless steel available, the cold rolled stainless steel coil distinguishes itself with superior precision, enhanced strength, and an exceptional surface finish. For industries that demand both durability and aesthetics, cold rolled stainless steel coil is a material of choice. This article Zhonggongte Metallurgical focuses on two critical aspects: the advantages of cold rolled stainless steel coil and its wide range of applications across different industries. By understanding these two dimensions, buyers and manufacturers can make informed decisions about how to use and source this high-performance material.

Advantages of Cold Rolled Stainless Steel Coil

Precision Dimensional Accuracy

One of the defining characteristics of a cold rolled stainless steel coil is its exceptional dimensional precision. Unlike hot rolled products, which may experience slight deviations in thickness and flatness due to high-temperature processing, cold rolled coils are manufactured at room temperature. This allows for extremely tight tolerances in both thickness and width, often within fractions of a millimeter. Such accuracy is crucial in industries that rely on automated assembly lines, where even minor inconsistencies can lead to machine errors, wasted material, and costly delays.

In addition, the improved flatness of cold rolled stainless steel coil makes it easier to process further into sheets, strips, or custom components without requiring extensive rework. This not only saves manufacturers time and resources but also ensures that the end product meets strict engineering specifications.

Superior Surface Finish

Surface quality plays a vital role in both the functionality and aesthetic appeal of stainless steel. The cold rolling process enhances the surface finish, creating a smooth, clean, and often reflective appearance. Depending on the final treatment, manufacturers can produce coils with different finishes such as 2B, Bright Annealed (BA), No.4 brushed, or HL (Hairline). Each finish is tailored for specific uses—for example, 2B is widely used in industrial equipment due to its balance of function and appearance, while BA is favored for decorative or high-visibility applications where a mirror-like shine is required.

A superior surface finish not only contributes to aesthetics but also adds to hygiene, as smooth surfaces are easier to clean and resistant to bacterial buildup. This makes cold rolled stainless steel coil especially valuable in sectors such as food processing, kitchen equipment, and healthcare facilities, where cleanliness is paramount.

Enhanced Mechanical Strength

Strength and durability are non-negotiable when it comes to materials used in critical infrastructure, vehicles, or heavy machinery. Cold rolling work-hardens the steel, thereby increasing its yield strength and hardness. The result is a product that resists deformation under heavy loads and offers improved fatigue resistance during long-term use.

For example, in automotive manufacturing, components made from cold rolled stainless steel coil can withstand vibration, heat, and stress without losing structural integrity. In construction, the added strength ensures that cladding, roofing, or structural reinforcements maintain their shape and reliability over decades. This durability reduces the need for frequent replacements, ultimately saving costs for end users.

Corrosion Resistance

A major advantage of stainless steel in general—and cold rolled stainless steel coil in particular—is its excellent resistance to corrosion. This property varies depending on the specific grade used. For instance, grade 304 is highly resistant to most forms of corrosion and is suitable for a wide range of indoor and outdoor applications. Grade 316, with its added molybdenum content, provides enhanced resistance to chlorides, making it the preferred choice for marine environments or chemical processing plants.

Cold rolling further refines the grain structure of the steel, which can improve its corrosion resistance and give it a more uniform surface that is less prone to localized rusting. In practical terms, this means longer-lasting performance even in environments exposed to moisture, chemicals, or extreme temperatures.

Aesthetic Versatility

In addition to functionality, aesthetics often drive material selection in industries such as architecture, interior design, and consumer appliances. Cold rolled stainless steel coil offers a clean, modern appearance that can be tailored to meet diverse design requirements. Whether a building calls for a sleek, reflective façade or an appliance requires a brushed, fingerprint-resistant finish, cold rolled coils can be produced to match the desired look without compromising on durability. This aesthetic versatility allows manufacturers and designers to combine form and function seamlessly, ensuring that the product is not only strong and long-lasting but also visually appealing.

Sustainability and Recyclability

With sustainability becoming a global priority, the fact that stainless steel is 100% recyclable adds significant value. Cold rolled stainless steel coil can be recycled repeatedly without losing its mechanical or chemical properties, making it an environmentally friendly option for industries seeking to reduce their carbon footprint.

Moreover, the long service life of cold rolled coils means fewer replacements and reduced consumption of raw materials over time. This contributes to cost savings and aligns with corporate sustainability goals. In markets where eco-conscious practices are a competitive advantage, choosing cold rolled stainless steel coil can help businesses strengthen their reputation and meet regulatory requirements.

Cost Efficiency Over Time

While cold rolled stainless steel coil may have a higher initial cost compared to hot rolled alternatives or other metals, its performance characteristics more than justify the investment. The material's durability, corrosion resistance, and low maintenance requirements significantly reduce long-term costs. For industries operating in challenging environments—such as offshore oil platforms, chemical plants, or large-scale infrastructure projects—the savings in repair, downtime, and replacement expenses are substantial.

In short, cold rolled stainless steel coil provides excellent value for money, delivering both immediate and long-term returns on investment.

Applications of Cold Rolled Stainless Steel Coil

Thanks to its outstanding properties, cold rolled stainless steel coil is applied across a wide range of industries. Below are the most important sectors where this material plays a critical role.

Automotive Industry

The automotive industry is one of the largest consumers of cold rolled stainless steel coil, using it in a variety of critical components. Exhaust systems, for example, require materials that can withstand extreme heat and corrosive gases, making stainless steel the perfect solution. Similarly, trims and decorative parts benefit from the sleek, polished look of cold rolled coils, which retain their appearance even after years of use.

Structural reinforcements within vehicles also rely on the added strength provided by cold rolling. By combining durability, corrosion resistance, and aesthetic appeal, cold rolled stainless steel coil ensures safety, reliability, and a premium finish in modern vehicles.

Construction and Architecture

In construction, both structural integrity and visual impact are important. Cold rolled stainless steel coil addresses both needs. Its corrosion resistance ensures that cladding, roofing, and façades remain intact and attractive for decades, even when exposed to pollution, rain, or extreme temperatures.

Architects value the material for its design flexibility, as it can be shaped, finished, and polished to suit contemporary aesthetics. From skyscraper façades to interior elevator panels, cold rolled stainless steel coil is a staple material that supports innovation in modern architecture while delivering proven performance.

Kitchen and Household Appliances

Stainless steel has long been the material of choice for kitchens, and cold rolled coils are the reason behind its widespread adoption. The smooth, easy-to-clean surface ensures hygiene in food preparation areas, while its durability guarantees long-lasting sinks, countertops, and appliances. Refrigerators, dishwashers, ovens, and microwaves often feature panels made from cold rolled stainless steel coil, combining practicality with a high-end appearance.

Its resistance to stains, heat, and scratches makes it ideal for demanding household use, ensuring that products remain functional and visually appealing for years.

Food and Beverage Industry

The strict hygiene standards in the food and beverage sector demand materials that can be cleaned easily and that resist corrosion from frequent exposure to water, chemicals, and organic acids. Cold rolled stainless steel coil fits this requirement perfectly. It is used in storage tanks, processing equipment, and conveyor systems, where its smooth surface prevents bacterial growth and allows for easy sterilization. By ensuring both food safety and operational efficiency, cold rolled stainless steel coil has become an essential material in food and beverage production facilities worldwide.

Industrial and Chemical Equipment

Industries handling corrosive chemicals or operating under extreme pressure rely on materials that offer both strength and resistance. Cold rolled stainless steel coil is widely used in the production of chemical tanks, heat exchangers, and pressure vessels. Its ability to maintain integrity under harsh conditions makes it indispensable in ensuring safe and continuous industrial operations. By reducing the risk of equipment failure and downtime, cold rolled coils directly contribute to improved productivity and cost savings for manufacturers.

Energy and Marine Applications

Few environments are as demanding as offshore platforms or marine vessels, where exposure to saltwater, high humidity, and mechanical stress is constant. Cold rolled stainless steel coil, especially in grades like 316, offers the resistance and strength required to withstand these conditions. In the energy sector, the material is also used in turbines, pipelines, and power generation equipment. Its reliability ensures safety and efficiency in industries where performance failures can have severe consequences.

The cold rolled stainless steel coil is far more than just a processed metal product; it is a critical enabler of modern industry. With its unmatched precision, mechanical strength, surface quality, and corrosion resistance, it delivers consistent performance across a wide range of applications. From automobiles and architecture to food processing and energy, cold rolled stainless steel coil is a material that ensures reliability, safety, and design excellence. By focusing on its advantages and applications, businesses and manufacturers can clearly see why cold rolled stainless steel coil remains one of the most trusted materials in global markets. For any enterprise seeking durability, cost efficiency, and versatility, this product stands as an essential investment.

https://www.zhonggongtemetal.com/Stainless-Steel-Coil

http://www.zhonggongtemetal.com

Jiangsu Zhonggongte Metallurgical Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.