- This topic is empty.

-

AuthorPosts

-

2025-07-28 at 3:39 pm #4256

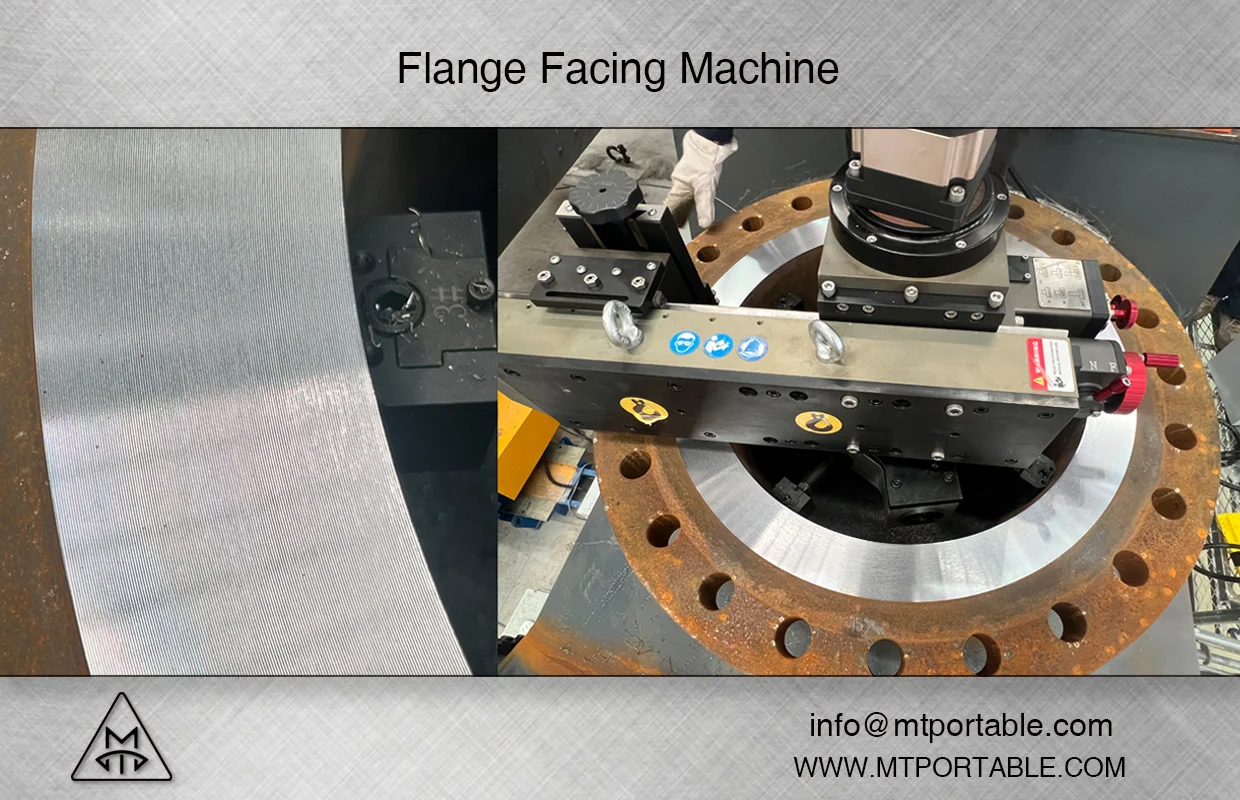

Precision Machining on the Move: FI40E Flange Facing Machine Delivers Power, Portability, and Performance

Wuxi, China – July 2025 — As industries demand tighter sealing tolerances and more responsive on-site maintenance solutions, the FI40 Flange Facing Machine series by MT Portable Machine emerges as a top-tier choice for flange refurbishment across the oil & gas, petrochemical, and power generation sectors. Engineered for high-precision field machining, the FI40 delivers rugged performance in a compact, modular form—backed by intelligent engineering and premium components.

The FI40 Flange Facer is designed for internal mounting and covers a wide machining diameter from 153 mm (6") to 1000 mm (40"), with an ID mounting range from 145 mm to 910 mm. The tool post provides a 102 mm (4") travel, while the machine offers six continuous feed rates for both facing and boring operations. This allows operators to produce finishes that comply with ASME B16.5 gramophone sealing standards, including flat face (FF), raised face (RF), ring-type joint (RTJ), and special groove profiles such as V grooves and lens rings.

Two models are available: the FI40P, powered by a Modec pneumatic motor (2.2 Hp / 1.7 kW) operating at 1.8 m³/min @ 0.6 MPa, and the FI40E, driven by a Panasonic electric servo motor (2.0 Hp / 1.5 kW), operating on 220-240V, 50/60 Hz. The FI40E delivers variable rotational speeds from 0 to 40 rpm, while the pneumatic version ranges from 10 to 33 rpm, giving users flexibility in matching speed to flange condition and material hardness.

What sets the FI40 apart is its engineering excellence. The machine features high-precision NSK bearings and a “V” linear guide system, ensuring outstanding rigidity and accuracy even under continuous load. The 360° swivel tool post enables precise machining of sealing grooves and special profiles, while the three different-sized quick-set mounting bases—each with micro-adjustable jaws—allow for rapid, accurate alignment during setup in any orientation.

Whether mounted horizontally, vertically, or inverted, the FI40 maintains cutting stability thanks to its low center of gravity and balanced drive system. The modular design also makes transport and assembly efficient. The FI40E weighs 350 kg and ships in a durable steel crate measuring 1250×640×775 mm, designed for harsh environments. Its robust waterproof case protects the unit during transportation and storage.

Lisa Sun, Technical Director at MT Portable Machine, stated: “We developed the FI40 series to meet the increasing demands of in-situ machining, where downtime must be minimized and performance must be uncompromising. From flange resurfacing and weld repair to ASME-compliant finishing, the FI40E is a machine our clients can rely on.”

Used extensively in refineries, offshore platforms, nuclear power stations, and chemical processing plants, the FI40 Flange Facing Machine represents a new benchmark in field machining—blending portability, versatility, and industrial-grade precision.

If you are facing challenges in flange facing for on-site projects, MT Portable Machine is ready to support you. Contact our technical team at info@mtportable.com to learn more about our ID flange facing machines, and discover how we can help streamline your welding preparation process.

http://www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd -

AuthorPosts

- You must be logged in to reply to this topic.